Roughly four billion pounds (1.8 billion kg) of old carpeting are landfilled each year. Comprised of different materials—nylon, polyester, latex backing, etc.—the stuff is inherently difficult to reprocess back into carpet (see

EBN

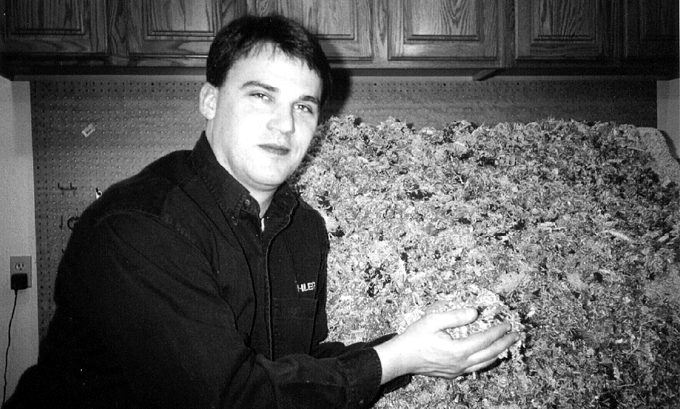

Vol. 6, No. 6). So how ‘bout simply shredding the stuff and turning it into a fiber insulation material? That’s exactly what entrepreneur Tom Deem wants to do.

Deem is an inventive sort of guy who works in a plumbing supply store in Philco, Illinois. When he wasn’t cutting pipe or finding the right plumbing fixtures for customers a few years ago, he thought a lot about the huge quantity of old carpet making its way into landfills. In 1993 he came up with the idea of turning old carpeting into loose-fill insulation for attic applications. So he bought a used brush chipper and tried shredding samples of carpeting.

That worked pretty well—the chipper broke the backing apart and left a fluffy fiber with a density of about 2 lb/ft3 (32 kg/m3). The product was not unlike cellulose insulation, and he found that it could be blown into attics using cellulose-blowing equipment.

Over the years, Deem had the good fortune of getting to know building scientist Bill Rose (with the Small Homes Research Council at the University of Illinois). He gave Rose a sample to carry out some quick thermal testing, and the stuff achieved a respectable R-3.3 per inch (RSI-0.6)—about the same as most fiberglass batt insulation and somewhat better than loose-fill fiberglass, though not quite as high as cellulose.

Deem has a patent pending on the insulation material, he’s experimenting with more advanced industrial shredding equipment, he has just incorporated his fledgling business as Recycled Carpet Technologies, Inc., and he’s having fire safety testing done by Underwriters Laboratories (UL). Just which standards this insulation material needs to meet are uncertain, however, because it is neither cellulose nor mineral fiber insulation. UL is going ahead with ASTM E-84 flame tunnel tests. Deem is optimistic that the material will do well in the testing, since carpeting passes the E-84 tests. If the insulation does not pass, he plans to mist it with fire retardants, as is done with cellulose.

Based on some quick tests at the

EBN product testing laboratory, we suspect the fire retardant will be necessary. A small sample maintained a flame when ignited with a match. In similar tests with other fiber insulation materials (fiberglass, cellulose, cotton), we have found none that will maintain flame. In addition to the flame, a noxious black smoke was given off.

In several calls to the carpet industry, we found no one who had heard about such an idea. Tim Blount, who manages the carpet recycling program at carpet resin supplier BASF has heard discussion of producing such a product from natural-fiber carpet (wool or cotton), but not from synthetic carpet. Blount doesn’t know of any inherent problems with the idea. “It should work for that,” he told

EBN.

Deem plans to package the insulation into 40-pound (18 kg) bags, each of which will cover roughly 19 square feet (1.8 m2) at a rating of R-38 (RSI-6.7). He expects the retail price to be $3.50 per bag. Some local price checking in Vermont and New Hampshire by

EBN found this to be 50% to 70% the cost of cellulose and about 40% the cost of loose-fill fiberglass for comparable insulation value and area coverage. Pending the outcome of fire testing, Deem hopes to begin selling his recycled carpet insulation by June of this year. He hasn’t yet set up any distribution agreements but expects to distribute the insulation through established channels. There remain lots of questions about recycled-carpet insulation, including indoor air quality issues, but this is a product we will definitely be keeping an eye on.

For more information:

Tom Deem, President

Recycled Carpet Technologies, Inc.

108 E. Stahl

Philco, IL 61864

217/684-2038

rct100@aol.com (e-mail)

Add new comment

To post a comment, you need to register for a BuildingGreen Basic membership (free) or login to your existing profile.