Blog Post

InPro's New BioPolymer

InPro's products, like others in this industry, have been dominated by vinyl (polyvinyl chloride, PVC) since the 1970s. The company gained the attention of BuildingGreen in 2003 when it introduced a non-PVC resin, EnviroGT, as a greener alternative to their own (and other) PVC products. We named the EnviroGT product line one of our 2003 Top-10 Green Building Products.

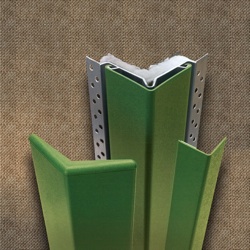

What has been really impressive about InPro since then is how thorough Matt Bennett (now vice president for product development) has been in pursuing greener products. For the past ten years, Bennett has been active with the U.S. Green Building Council, closely following green building trends, attending conferences, and asking lots and lots of questions. I most recently saw him at a fairly high-level retreat on low-impact building materials in San Francisco: the Build Well Symposium. Through those efforts, Bennett and InPro have been able to be green leaders in their particular segment of the building products industry. The latest material is a fascinating one: BioPolyPETG+, used in the G2 product line. It looks and behaves like vinyl (PVC), seems to meet all of the applicable performance tests, and has some attractive green attributes. BioPolymerPETG+ (InPro's tradename for the material) blends corn-based biopolymer with PETG (a copolymer of polyethylene terephthalate--polyester--that contains cyclohexane dimethanol); this PETG is partially derived from pre-consumer recycled content. BioPolymerPETG+ is used in a variety of wall-protection, corner-guard, and chair rail products. (Vinyl and a polycarbonate/ABS material are still used by the company in its more conventional product lines, and even the new G2 line uses molded ABS end-caps--rather than BioPolymerPETG+ throughout.)

BioPolymerPETG+, is free of halogens (chlorine, bromine, etc.), heavy metals, bisphenol-A (BPA), and other hazardous constituents. InPro gave BuildingGreen access to proprietary information about the chemicals used in producing BioPolymerPETG+, and we did not uncover any persistent bioaccumulative toxins (PBTs) or other ingredients considered highly problematic. For more about what's involved in assessing chemical risks in building products, see Jennifer Atlee's excellent article, Chemistry for Designers: Understanding Hazards in Building Products, in our March, 2009 issue of EBN (premium content for members).

There is a reasonable debate about how appropriate it is to produce building materials from agricultural crops, such as corn. My perspective on this is that, while a lot of unsustainable practices are used in farming today, it is worthwhile promoting biopolymers, because these materials demonstrate the potential of moving beyond fossil fuels as raw materials for plastics. If corn- and soy-based polymers can be successfully used in producing durable plastics, that will fuel research into better biobased raw materials, such as those made from agricultural waste (corn stalks, bagasse from sugar cane, straw, etc.).

By mixing a biobased polymer with a fossil-fuel-based polymer (PETG), end-of-life performance is uncertain. When used alone, biopolymers will biodegrade, but biodegradability is at best compromised and more likely prevented by the addition of a non-biobased polymer. At the same time, while PETG alone is a recyclable plastic, adding the biopolymer to this makes end-of-life recycling doubtful--though the jury is still out on that.

SUPPORT INDEPENDENT SUSTAINABILITY REPORTING

BuildingGreen relies on our premium members, not on advertisers. Help make our work possible.

See membership options »BioPolymerPETG+ contains 20% pre-consumer recycled content and 20% corn-based polymer, a rapidly renewable material. As a result, it can help to achieve two credits in the LEED Rating System for recycled-content and rapidly renewable materials (MRc4 and MRc6). Just last week, the material also gained certification through Greenguard and Greenguard Children & Schools for indoor air quality, which might contribute to Indoor Environmental Quality Credit 3.2 in LEED.

We applaud InPro's ongoing efforts to create greener building products, and we look forward to future offerings from the company.

For more information:

InPro Corporation

Muskego, Wisconsin

800-222-5556

www.inprocorp.comI invite you to share comments on this blog. What other green products should I be covering?

To keep up with my latest articles and musings, you can sign up for my Twitter feeds.

See more on this product in the GreenSpec Guide

Published March 25, 2010 Permalink Citation

(2010, March 25). InPro's New BioPolymer. Retrieved from https://www.buildinggreen.com/news-article/inpros-new-biopolymer

Add new comment

To post a comment, you need to register for a BuildingGreen Basic membership (free) or login to your existing profile.