What is the polymer/ foil combination that keeps the Argon / Krypton / Xenon from diffusing out?

Noble gases are notoriously difficult to keep enclosed as an Ar(1) is very small compared to a

N2. Also, it would be best if these things could hold their gas for a few decades, not just 2 or 3

years as is the case with Argon filled windows. If it is not permissible to state the combination of

polymer / foil, can it be stated with certainty how long 90% of the gas will stay inside? Thanks,

Blog Post

Innovative Gas-Filled Panel Insulation from Fi-Foil

A new gas-filled panel insulation material that consists of pockets of low-conductivity gas in a honeycomb foil substrate provides insulation levels as high at R-11 for inch-and-a-half-thick panels.

About gas-filled panels

It is well-known that low-conductivity gasses, such as argon and krypton, significantly improve the energy performance of windows. They do this because they have a lower gas-phase conductivity than air, so they retard heat flow through the window.

Researchers at Lawrence Berkeley National Laboratory (LBNL) have long argued that this same principle could be used to create high-performance building insulation, and they developed technology for encapsulating gasses in flexible foil and plastic honeycomb material. LBNL licensed this technology to the radiant barrier manufacturer, Fi-Foil, which introduced a gas-filled panel (GFP) insulation material at the International Builders Showin January of this year.

Fi-Foil's GFP Insulation

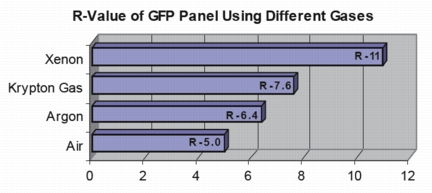

Fi-Foil's GFP Insulation has inner and outer skins comprised of an aluminum foil-polymer laminate and five internal alumized low-emissivity (low-e) films that expand with gas to form a 1-1/2-inch-thick (38 mm) flexible honeycomb panel. The sealed exterior skins contain the gas-fill. The panels are available with air, argon, krypton, or xenon as the gas-fill, providing insulating values of R-5.0 for air, R-6.4 for argon, R-7.6 for krypton, and R-11 for xenon. On a per-inch basis, these insulating values range from R-3.3 for air to R-7.3 for xenon. When installed with an air space on one or both sides, the R-value will be higher--as is the case with radiant-barrier insulation.

SUPPORT INDEPENDENT SUSTAINABILITY REPORTING

BuildingGreen relies on our premium members, not on advertisers. Help make our work possible.

See membership options »

Fi-Foil's GFP Insulation can be used in residential and commercial applications. Because it is flexible and depends on remaining tightly sealed for its rated energy performance, GFP Insulation is most appropriate for cavity-fill and plenum applications--for example, insulating exterior plenum walls or laying the lightweight panels on top of suspended ceilings in commercial buildings. It could also be incorporated into doors, water heaters, refrigerators, and other appliances by original equipment manufacturers (OEMs). Fi-Foil licenses the technology only for building applications.

The foil layers and the gas fills are inert, so very safe for both installers and homeowners. There are no fibers, no offgassing, and the panels are mold resistant and will not absorb moisture.

While the GFP panels need to be protected from puncture, they will not lose all performance if damaged. If punctured, the panels will maintain their shape and thickness, but air will gradually replace the argon or other low-conductivity gas in the honeycomb structure. Unlike windows that lose their seal (and gas-fill), fogging is not an issue with these insulation panels, because they are opaque.

Ships flat, inflated on-site

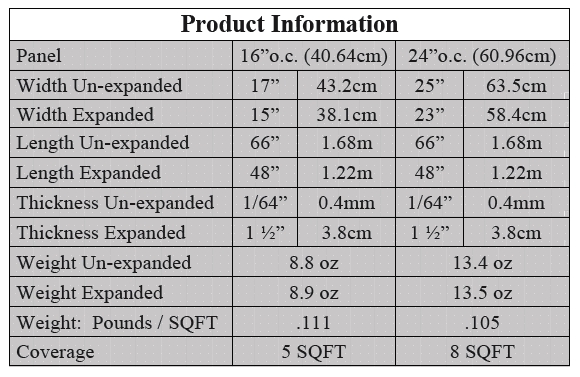

A unique aspect of GFP Insulation is that it ships totally flat and is inflated with air or low-conductivity gas on-site. Fi-Foil has specified a simple filling device that automatically shuts off after the panel has been expanded to the desired thickness. Canisters of the desired low-conductivity gas can be purchased from a local welding supply store or specialized gas supplier. The filling device can be consigned from the company or purchased. A big advantage of shipping GFP Insulation unexpanded is transportation energy savings. The uninflated panel is just 1/64th of an inch thick, according to Bill Lippy, senor vice president and chief marketing officer at Fi-Foil. "You're not shipping air," he noted.

More expensive than fiberglass, cheaper than spray polyurethane foam

Fi-Foil would not provide an exact price for the product, but Lippy told me that it's more expensive than fiberglass and less expensive than spray polyurethane foam (SPF).

To date, Fi-Foil has provided argon- and air-filled panels only, but the company has the ability to provide krypton and xenon, though at a higher cost. By mixing gases, "you can customize your R-value," Lippy told me.

The product was used recently in a renovation project at a LEED-Gold-rated New York Power Authority building in White Plains, New York. Argon-filled panels were installed on the 5th floor of the building in September 2009 (see photos), and the other floors of the 13-story building to be insulated in 2011. Added to the existing two inches of foil-faced fiberglass, the system R-value has been increased to R-24.2.

Final thoughts

Fi-Foil's GFP Insulation is a neat product for sure, and I look forward to seeing how much interest it generates in the building industry. I won't be at all surprised to see this product become fairly common in refrigerators and other appliances.

For more information:

Fi-Foil Company

Auburndale, Florida

800-448-3401, 863-965-1846

I invite you to share comments on this blog. Do you think GFP Insulation has potential as a building insulation material?

Alex Wilson is the founder of BuildingGreen, LLC and executive editor of Environmental Building News. He also posts a weekly Energy Solutions blog. To keep up with his latest articles and musings, you can sign up for his Twitter feeds.

See more on this product in the GreenSpec Guide

Published July 8, 2010 Permalink Citation

(2010, July 8). Innovative Gas-Filled Panel Insulation from Fi-Foil. Retrieved from https://www.buildinggreen.com/news-article/innovative-gas-filled-panel-insulation-fi-foil

Add new comment

To post a comment, you need to register for a BuildingGreen Basic membership (free) or login to your existing profile.