Another Greenbuild conference has come and gone, with its frenetic activity, informative educational sessions, many meetings, and all-important networking.

This year I focused much of my time and attention on the Product Expo—and it took a lot of both! At the U.S. Green Building Council’s first Greenbuild conference in Austin, Texas, eight years ago, there were just 250 exhibitors; in Phoenix there were 1,100 spread over 11.5 acres (4.7 ha) in two exhibit halls at the Phoenix Convention Center. I scrambled to walk all those aisles and stopped at a good many—though certainly not all—of the booths. On the following pages are some brief snippets of what I found most exciting, covering almost 40 products and services. I feel very good about most of these products, though a few raise some doubts.

This is by no means a comprehensive list of what was there; I may well have missed some particularly exciting new products. But for those who weren’t able to get to Phoenix in November or didn’t have time to make it through the expo, this survey offers a glimpse of some companies and products that stood out from the rest. I invite you to share your comments with your own observations—products I missed or misunderstood, or anything else noteworthy.

Exciting Products from Greenbuild Phoenix

While the products described in the following pages are scattered over a wide range of applications, most have been grouped under general headings.

Rinnai

Rinnai has a new, 95% efficient, condensing tankless water heater. The RC98HPi is designed for interior mounting; delivers 9.8 gallons per minute (gpm; 37 lpm) at a 35°F (19°C) temperature rise and 3.8 gpm (14 lpm) at a 100°F (56°C) temperature rise; and uses natural gas or propane at an input rate of 10,000–199,000 Btu/hour (2.9–58 kW). The energy factor is listed at 0.93. Solving a problem with some tankless water heaters used with low-flow faucets, this water heater will activate at a flow rate as low as 0.4 gpm (1.5 lpm).

www.rinnai.usVenmar Ventilation of Canada showed off its state-of-the-art EKO residential heat-recovery ventilator (HRV). The EKO 1.5 uses an electronically commutated motor (ECM) to deliver 2.53 cfm per watt, which the company claims is the highest efficiency of any HRV in the industry. At the lowest of four speeds, it uses just 13.5 watts to deliver 40–80 cfm. Included with the HRV is a highly sophisticated and, well, pretty cool Altitude wall control, which displays graphically what the HRV is doing.

www.venmar.caRiteHite makes high-volume, low-speed fans—like Big Ass Fans, which has been a prominent exhibitor at recent green building conferences. RiteHite claims that its Revolution series offers the highest-efficiency air delivery of any ceiling fan. It certainly looks to have very good specifications. Fans are available with diameters from 8–24 ft (2.4–7.3 m) providing up to 428,000 cfm of air flow. Ceiling fans are green because, by moving air, they raise the air temperature at which people are comfortable; RiteHite claims that 2–3 miles per hour (0.9–1.3 meters per second) of air flow is comparable to lowering the air temperature 7°F–11°F (4°C–6°C).

www.ritehitefans.comThe Power-Pipe drainwater heat recovery system from

RenewABILITY Energy isn’t new, but it’s exciting enough to remind readers about. It is one of several systems that capture waste heat from shower drains for preheating hot water. It consists of multiple, parallel lengths of flattened copper pipe wrapped around a section of copper drainpipe; cold water circulates through the small-diameter outer pipe before reaching the water heater. It is appropriate for homes as well as commercial, industrial, and institutional buildings. According to company president Gerald Van Decker, over 50 builders are now using the system, and both Sears and Home Depot are carrying it in Canada. www.renewability.com

Panel products and interior finishes

The German company

Pinta Acoustic has introduced to the U.S. a great-looking acoustic ceiling panel and wall tile called Phonstop. The panels are made from 100% post-consumer recycled glass bottles, which are ground and sintered to form a rigid, lightweight, porous panel. Unlike mineral wool acoustic panels, a binder is not required for the Phonstop panels, which achieve Class 1 fire-resistance as well as flame-spread and smoke developed ratings of 0 (based on ASTM E-84) without the use of flame retardants. Compressive strength is 165 psi. Phonstop V, in 2" (50 mm) thickness, adheres directly to walls or ceilings; Phonstop E, in 1" (25 mm) thickness, is installed into standard ceiling grids. www.pinta-acoustic.com

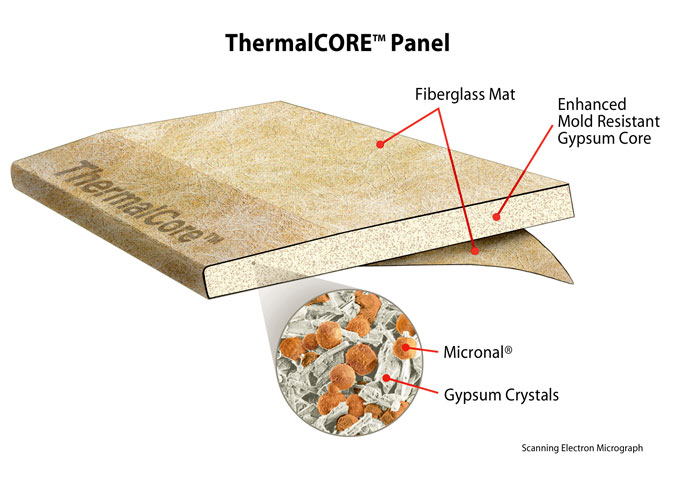

National Gypsum

National Gypsum introduced its ThermalCORE phase-change drywall. Phase-change materials (PCMs) take advantage of the fact that materials changing phase (as from solid to liquid) either store or release a great deal of heat with a very small change in temperature. ThermalCORE uses a paraffin-based material called Micronal, made by BASF, that melts at 73°F ± 2°F (23°C ± 1°C), storing approximately 22 Btus per square foot (70 watt-hours/m

2). Micronal consists of tiny spheres of paraffin surrounded by an acrylic shell with a diameter of just 5–10 microns (about half the size of portland cement particles). While not yet on the market, ThermalCORE could be North America’s first truly practical PCM for building applications; a similar product is in use in Germany

and was used in the German submission that won the 2009 Solar Decathlon (see EBN Dec. 2009). www.thermalcore.infoRichlite makes a durable countertop material from paper and phenolic-formaldehyde resin. All of Richlite’s paper content (60%–70% of the material) is now either certified to the Forest Stewardship Council’s (FSC) standards or derived from 100% post-consumer recycled paper (the R100 line). As for concerns about emissions from the phenol-formaldehyde resin, the material is certified by Greenguard Children & Schools and has measured formaldehyde levels of 0.001 parts per million, which is two orders of magnitude lower than typical background levels in the U.S. www.richlite.com

The Japanese company

Tagawa Sangyo exhibited its

Shikkui lime plaster at Greenbuild. The product, which has received Cradle to Cradle Silver certification from McDonough Braungart Design Chemistry (MBDC), is being distributed in the U.S. by Tariki, Ltd., with distribution points in Boston and Los Angeles. (For more on the benefits and drawbacks of lime plasters and stuccos, and an American Clay product made domestically, see

EBN Oct. 2008.) www.shikkui.comSurfaceWorks makes the GreenWorks line of particleboard-core work surfaces and tabletops. These products are available with no added urea formaldehyde and FSC-certified substrate; with various surfacing options, including Forbo linoleum and Greenguard Children & Schools-certified high-pressure laminate; and with various options for edging, including bamboo, FSC-certified wood, and a urethane made from 65% vegetable oils. Oddly, FSC-certified surface veneers are not listed as an option. www.surfaceworks.us

Plumbing fixtures and water-saving components

One of the big surprises at Greenbuild was learning that most of the major plumbing equipment manufacturers, including

Moen,

American Standard,

Kohler,

Delta Faucet, and

TOTO, have shifted 100% of their lavatory faucets to maximum-1.5 gpm (5.7 lpm) flow rates—the level required to achieve EPA WaterSense certification. This represents a 32% reduction in water use when compared to the federal standard of 2.2 gpm (8.3 lpm). For most of these companies, this change applies to both residential and commercial products. As was clearly demonstrated in many of the exhibits, with good aeration or laminar-flow designs, a 1.5 gpm lavatory faucet is virtually indistinguishable from a 2.2 gpm product.

Along with the conversion to 1.5 gpm faucets,

American Standard has a new FloWise Flush-Free Urinal that’s manufactured by ZeroFlush and branded American Standard; it comes in three styles. The company has also introduced the Washbrook FloWise eighth-gallon (0.5 lpf) urinal, the H2Option dual-flush toilet using 1.6/1.0 gpf (6/3.8 lpf), the Yorkville pressure-assist 1.1 gpf (4.2 lpf) toilet (using a WDI EcoFlush pressure-flush module), and an interesting FloWise showerhead that is adjustable from 1.5 to 2.0 gpm (5.7 to 7.6 lpm); if you adjust it higher, it reverts back to 1.5 gpm when next turned on. www.americanstandard-us.comKohler was most excited about its Insight Technology for hands-free faucets and flushometer toilets. This is a hybrid capacitor that achieves, Kohler claims, a 30-year battery life for sensor faucets based on 1.5 million uses—that’s once every 10 minutes, day and night, for 30 years. Another significant innovation premiered at Greenbuild was the hands-free Wave technology for sensor-flush toilets that prevents false flushes. A user flushes a toilet equipped with Wave technology manually—without touching anything—by passing a hand over the top of the sensor, breaking a vertical beam. Kohler also showed off its new eighth-gallon (0.5 lpf) Barden urinal. In October, for the second year in a row, Kohler was named the U.S. Environmental Protection Agency (EPA) WaterSense Partner of the Year in the manufacturer category. www.kohler.comAustralian manufacturer

Caroma introduced in May 2009 a redesigned version of its H2Zero waterless urinal (see

EBN Nov. 2007). The new model includes both the elastomeric mechanical seal (trap) that the previous model used and, below that, a more conventional “P” trap that uses urine (rather than the usual water) to provide the code-required liquid trap. While Caroma believes that this U.S. code requirement is unnecessary and that mechanical seals alone can do the job, redesigning the urinal was easier than changing long-established plumbing codes (for more on this issue see

EBN Apr. 2008). The mechanical seal is made of silicone and rated for 10,000 uses. A big advantage of this system is that there’s no plant-oil trap fluid (found in most waterless urinals). Not only is that fluid expensive, but some experts worry that it will become a problem in wastewater treatment plants as waterless urinal use grows. Without the worry of losing the plant-oil trap fluid, custodial staff can periodically flush a gallon of water down the drain of the H2Zero to clear salt deposits—the biggest hindrance to long-term performance of waterless urinals. The City of Los Angeles recently approved the H2Zero urinal and offers a $400 rebate on it. www.caromausa.com

Along with the conversion to low-flow faucets,

Delta Faucet has a new Proximity Sensing Technology in its commercial line that employs a 4" (100 mm) electric field around the entire faucet; when something enters that field, the faucet turns on. It’s a smart system that recalibrates, so it doesn’t keep running if the object next to it doesn’t move. While sensor-activated faucets have not been shown to actually reduce water use, the very clear trend in plumbing fixtures is toward hands-free for hygiene reasons, and we can hope to see continued innovation to improve efficiency. In its residential line, Delta has introduced the Touch2O Technology for kitchen faucets; touching any part of the faucet or handle turns the flow on and off. This may save water by allowing easier on-off control without affecting the temperature mix or flow rate. www.deltafaucet.com, www.deltacommercialfaucets.com

TOTO

TOTO featured its Clean Dry Hand Dryer, which is now available in the U.S. Having tried out a lot of fast-acting hand dryers, I was impressed with how quiet this product is—though a noisy trade show floor is not the ideal test site! TOTO’s highly regarded, 1.28 gpf (4.8 lpf) Drake II toilet has been redesigned so that water now enters the bowl on both sides for better bowl-wash; and the company also showed a 1.28 gpf commercial flushometer toilet. For the shower, TOTO introduced the Gyrostream body spray, which provides a swirling flow of 0.8 gpm (3.0 lpm) that massages the user. We believe that body sprays, which provide a horizontal stream of water from the shower wall and are typically installed in multiples, are unnecessary and undesirable in a shower, but if a client insists, this product at least significantly reduces the flow. TOTO also introduced a simple push-button control to turn a shower or body spray off and on (to save water while lathering).

www.totousa.comSloan Valve showed off lots of products, including its eighth-gallon (0.5 lpf) urinal and a cool Ecos Dual-Flush sensor flushometer for toilets that chooses a light flush or a full flush based on time spent on the toilet (65-second threshold for the full flush). The company also has a prototype Alpine tenth-gallon (0.38 lpf) urinal that fills an internal basin with the flush volume and then dumps it during the flush to deliver the full volume all at once for more effective clearing of the drain line—a strategy to reduce salt buildup. Finally, Sloan’s FlushMate IV pressure-assist flush mechanism, used in dozens of top-performing toilets, is now quieter (83 dB).

www.sloanvalve.comI’ve been writing about water savings for a long time but had never heard about Waterbury, Connecticut, company

Neoperl, which has been producing faucet aerators, flow regulators, check valves, and related products since 1928 and is the only company making aerators in the U.S. Neoperl mostly sells to original equipment manufacturers (OEMs) such as Kohler, Sloan Valve, and TOTO, but some of its products are also available directly to consumers through Home Depot. The company’s aerators are available in a wide range of flow rates; many carry WaterSense certification. www.neoperl.comThe small Calgary, Alberta, company

TapMaster was exhibiting foot- and knee-operated faucet controls at Greenbuild. I had a great chat with the inventor, Peter Pubben, and his wife, who together run the company. We’ve had this product in our

GreenSpec database for years, and I’ve been using one at home that works as flawlessly now as when it was installed more than five years ago. But I’ve never really known how it works. I still can’t say I fully grasp the operation, but it’s ingenious, and the way it’s been engineered results in much less water-hammer (clanking pipes when you turn fixtures on and off) than more conventional foot-controls. These hands-free controls can save water and energy by allowing users to turn on the tap (at the temperature and flow rate they’ve set) quickly and easily—when washing pots and pans, for example. www.tapmaster.ca

Windows, doors, and fenestration-related products

RavenBrick displayed one of the most innovative products I saw at Greenbuild: RavenWindow, a

thermochromic glazing that darkens passively as it is heated. On a hot, sunny day this tinting reduces the solar transmissivity of a window from about 60% to 8%, dramatically reducing solar heat gain and cooling costs. The tinting occurs without any electricity; when the glazing cools, it reverts back to its clear state. The temperature at which RavenWindow darkens is set at the time of manufacture; once the glazing is produced, that property cannot be changed. The tinting is achieved with an organic material sandwiched between two layers of glass. Unlike some organic

electrochromic glazing materials that have come and gone in recent years, the material used by RavenBrick is highly durable, according to CEO Alex Burney. The first product will be shipped in March 2010, Burney says, for an installation in a new building at the National Renewable Energy Laboratory (NREL). The company is projecting a cost of $25/ft2 ($270/m2), which is lower than that of SageGlass, a competing electrochromic glazing (see

EBN June 2006). Like SageGlass, RavenWindow technology will be licensed to partner manufacturers that will produce the windows and glazing systems. RavenBrick also showed off a spandrel glazing system, RavenSkin, that incorporates a PCM; the hope is to introduce it commercially in 2011. www.ravenbrick.com

I never thought I’d get excited about a garage door, but then I happened upon the

Rytec booth. The company makes commercial garage-type doors that open and close really quickly. I hadn’t thought much about this before, but in a garage or warehouse, the time a door is open is a major determinant of energy use—often much more significant than how well-insulated the doors are. A great video shown (over and over) in the company’s booth, and on its website, shows side-by-side doors at an automotive shop. The Rytec door cycles open and closed in about six seconds, versus almost a minute for the other door. www.rytecdoors.comSavannah Trims, one of the few U.S. companies to produce an exterior louvered blind, continues to roll out interesting products. The company’s latest innovation is a new solar-powered motor option for SkyShield exterior blinds. Exterior louvered blinds, very common in Europe, block unwanted heat gain more effectively than interior blinds, because they keep the sunlight from passing through the glazing. They can also provide security benefits. www.savannahtrims.comAmong the more interesting products introduced at Greenbuild was the Alluminate interior lightshelf from

Lamcel. It’s a three-foot-deep (0.9 m), lightweight, aluminum-honeycomb product with a curved (parabolic-like) profile that reflects light deep into the room. With a highly polished top surface (94% reflectivity), it disperses light much more effectively than white, planar lightshelves—150% better, according to the manufacturer. In a commercial building with high ceilings, the lightshelf is typically installed about seven feet (2.1 m) above the floor, and it reflects light coming through clear windows above that plane. Information on the product does not yet appear to be on the company’s website. www.lamcel.com

Lighting, electrical, and instrumentation

Lunera Lighting has introduced an attractive commercial LED lighting fixture that provides extremely uniform light. Available in linear (6.7" x 4'; 17 x 122 cm) or square (2' x 2'; 61 x 61 cm) configurations, Lunera fixtures provide a very respectable efficacy of about 61 lumens per watt. The fixtures are fully dimmable, and available with color temperatures of 3,000K, 4,000K, and 5,000K; the rated life is 50,000 hours with 70% lumen maintenance. www.lunera.comSouthwire has a new electrical cable with the lead oxide taken out. This isn’t as exciting as it would be if Southwire, North America’s leading producer of electrical cable for building wiring (Romex brand) as well as power distribution, offered a halogen-free product, but it’s great to see the company exhibiting at Greenbuild and at least talking about green issues.

southwire.com

Illumra

Illumra is one of a number of really cool control systems for hospitality lighting and HVAC systems using wireless

EnOcean technology. Guests in Illumra-equipped hotel rooms use a key card to unlock the door, then put the key in a key-card reader in the room; this activates lighting and HVAC controls. When the hotel guests leave, they take the key card out of the reader, turning off lights and resetting HVAC controls to energy-saving default settings. The beauty of the EnOcean wireless technology is that Illumra systems can be installed in existing rooms very easily and quickly. For more on Illumra, see

EBN Dec. 2009; for more on EnOcean (a BuildingGreen Top-10 product in 2007), see

EBN Dec. 2007. www.illumra.com

GrayWolf Sensing Solutions manufactures a wide range of monitoring equipment for volatile organic compounds (VOCs), carbon dioxide, carbon monoxide, ozone, hydrogen sulfide, and other chemicals, as well as temperature and relative humidity. Different probes are required for different measurements. The target market for the product line includes facility managers, indoor air quality consultants, environmental engineers, and building scientists. The company also offers a wide range of data collection, reporting, and software components. Typical system costs are about $7,500. www.wolfsense.com

Rainwater harvesting components and systems

There were a lot of rainwater harvesting systems on display at Greenbuild—more than I’ve ever seen. Clearly, there is growing concern about water supplies, and rainwater harvesting systems can be one part of the solution.

BRAE is based in North Carolina and offers a full range of residential and commercial rainwater systems. Rather than manufacturing components and systems, BRAE is a designer and packager; it has installed over 1,000 systems since its founding in 2002. www.braewater.comConservation Technology has seemingly been around forever, with new product introductions every time I turn around. At Greenbuild the company showed off a number of new rainwater harvesting products, including controllers, pumps (including a model with a variable-frequency drive), and tanks. It also has a new green roof system: the ultra-lightweight Drainage Plate System. www.conservationtechnology.comRH2ONorth America makes both residential and commercial rainwater harvesting systems. The products are imported from Germany, and the primary North American presence is (so far) in Canada. Systems include a full range of sophisticated components, including rainwater filters, calming inlets, overflow siphons, floating suction filters, and tanks. www.ourh2o.comJay R. Smith Manufacturing Company manufactures a variety of rainwater harvesting components and systems for both commercial and residential applications. With over 5,000 systems installed, not including its rain barrel systems, the company claims to be the largest manufacturer of rainwater harvesting systems in the country. Its products are primarily related to rainwater collection and filtration, not tanks. Jay R. Smith partners with Rain-water Management Solutions in the design and specification of systems. www.jrsmith.com

Wood products

MBDC had a booth focused on its Cradle to Cradle product certification, where it displayed Bark House, a residential siding made by

Highland Craftsmen from the bark of the tulip tree (Leriodendron tulipifera), which is sometimes—incorrectly—referred to as a poplar. The bark, a byproduct, is peeled from recently felled trees, cut to size, flattened, fully kiln-dried, and heat-sterilized. The bark itself provides its own “backing” and weatherproof layer. And it looks really cool—rather like, well, bark. The cost is fairly reasonable, too: about $6–$9 per square foot ($70–$100/m2) for the material or $12–$14 per square foot ($130–$150/m2) installed. BuildingGreen reviewed Bark House for our

GreenSpec directory, but I had never really grasped one of the real beauties of this product: when you want to replace it, you just pull it off and throw it into the woods to decompose. The product has become one of the few building products to earn a Cradle to Cradle Gold rating from MBDC. www.barkhouse.comAccoya from

Titan Wood was introduced in North America at the 2008 Greenbuild conference, but we somehow missed it. It is wood that has been treated with acetic anhydride (acetylation) to make it more stable and rot-resistant. The sample I picked up still has a distinctive vinegar smell—like salt-and-vinegar potato chips. The acetylation process has been known for a long time—since 1928—but has only recently entered the market: in Europe in 2004 and North America in 2008. The process works by converting free hydroxyl (OH) groups into acetyl groups, thereby removing the primary sites that absorb and release water. Titan Wood is currently made with radiata pine from New Zealand, but Accoya hopes to license the technology to a North American company that will use a native softwood. Titan Wood carries a surprisingly long 50-year warranty for aboveground applications and a 25-year warranty for belowground. All of the product is certified to the FSC mixed-sources standard, and the company expects to receive Cradle to Cradle certification at the Gold level shortly. The wood is more expensive than ACQ-treated wood but less expensive than tropical woods. Applications, according to Accoya, include outdoor decking, siding, window frames, doors, and outdoor furniture. Among our unanswered questions are whether the residual acetic acid in the wood causes corrosion problems (we suspect that it does) and whether there are indoor air quality problems associated with offgassing; we plan to run a more comprehensive product review in

EBN in the future. www.accoya.com

Water treatment and wastewater

Worrell Water Technologies

Worrell Water Technologies produces the Living Machine ecological wastewater treatment systems (see

EBN July 1996). Now based in Charlottesville, Virginia (having moved from Taos, New Mexico), the company seems to be expanding its visibility and sophistication. Based initially on technology developed by biologist John Todd, Ph.D., Living Machine technology has evolved considerably in recent years. At Greenbuild, the company promoted its “Next Gen Living Machine,” which simulates highly productive tidal ecosystems by filling and emptying cyclically, thus achieving better oxygenation. (We’re not sure about the energy implications of this feature.) The company has also shifted to a solid medium and now offers more advanced computer controls as well as remote monitoring. Used primarily in institutional and commercial facilities, Living Machine systems were recently selected for testing by the Department of Defense for possible use in remote military facilities. www.worrellwater.com

Greenbuild exhibitor

Burgis Envirolutions showed off a real oddball product: the ORCA Green (Organic Refuse Conversion Alternative). ORCA is a waste-management appliance for foodservice facilities that uses “bio-chips” impregnated with microorganisms to decompose food waste and compostable materials, producing a liquid (mostly water) that is sent down the drain with other wastewater. The advantage is a reduction in solid waste, but I have yet to be convinced that there is an environmental benefit to this system. In fact, if it increases the biochemical oxygen demand (BOD) of the wastewater, and if that increases energy and chemical use at sewage treatment plants, it is possible that the ORCA could have a net-negative environmental impact—particularly if the alternative is grinding and composting as a soil amendment. We hope to take an in-depth look at food waste and organics in wastewater in

EBN in the future and will investigate this product further for that article. www.burgisenviro.com

Living wall systems

Greenwalls modular planting systems were on display from

McCaren Designs. This living wall system relies on hydroponic growing in open-cell foam plugs. The company claims that its system could use graywater or rainwater, and it promotes indoor air quality benefits (see

EBN Oct. 2008 for more on possible benefits of indoor plants). The company did its first installation in 1993 but has installed just a handful of systems since. A large, 1,900 ft2 (180 m2) system is being installed in Canada currently, and a Greenwalls system is in use at a New York City Whole Foods store. www.greenwalls.comAnother living wall company, EcoWalls, was also displaying at Greenbuild. This New Jersey company designs, installs, and maintains systems in the mid-Atlantic states as well as Florida. About 15 of its systems have been installed to date. For indoor walls (the most common), low-light tropical plants are used; for outdoor applications, sedums or other plants may be used. The company has a close affiliation with Rutgers University, where its two founders studied, and also works with the National Foliage Foundation, which is researching volatile organic compound removal and other potential indoor air quality benefits of living walls. www.greenecowalls.com

Miscellaneous products

Among the most talked-about new products at Greenbuild was

CalStar fly ash brick. It’s an unfired brick, like concrete brick, but it uses Class C fly ash (about 40% by weight) as the binder, rather than portland cement. If this brick performs as the manufacturer claims and if the hazardous components are indeed locked up (as they are with vitrified brick), then this could be a dynamite product. www.calstarproducts.comEBN has long promoted the benefits of good entryway track-off entry systems (see

EBN Oct. 2001). In June 2009

EcoPath introduced an entryway track-off product with a host of green features in addition to the obvious indoor air quality benefits. Its BioGrip non-skid underlayment is made from natural rubber, with a fleece inter-layer made from 100% post-consumer recycled PET bottles. An EnviroCel layer is made from soy-based polyols and a fly ash constituent called Celceram. Durable face fibers are made from virgin polypropylene or nylon. Different abrasion levels are provided for different portions of the track-off system. The company will also take back product for recycling at the end of its useful life through its ReField program. www.ecopathmats.com

Final Thoughts

Even though I’ve been researching and writing about green building products for 20-odd years, I’m still always excited to learn about the new stuff coming out, and Greenbuild has become the leading place to see what’s new.

A few of the products mentioned here will return to the pages of

EBN with more in-depth product reviews or coverage in relevant feature articles. To learn more in the meantime, check out the websites listed with the brief product descriptions, or visit the Greenbuild 2009 website to view the full Expo Guide. Please share your own impressions using the comments field below.

– Alex Wilson

For more information:

Greenbuild 2009

www.greenbuildexpo.org