The American Institute of Architects (AIA) Committee on the Environment (COTE) has been issuing Top Ten Awards for nearly 20 years now, and its winners now number 189. The award is meant to shine a light on each project individually as a model and case study for sustainable design. COTE has discovered, however, that grouped and analyzed together, the projects also help reveal a high-level view of the trends and evolutions of sustainable design.

The American Institute of Architects (AIA) Committee on the Environment (COTE) has been issuing Top Ten Awards for nearly 20 years now, and its winners now number 189. The award is meant to shine a light on each project individually as a model and case study for sustainable design. COTE has discovered, however, that grouped and analyzed together, the projects also help reveal a high-level view of the trends and evolutions of sustainable design.

In a new report, “Lessons from the Leading Edge,” COTE takes a look at what this historical group of winners has in common and uses the data to give a rough picture of performance.

How high do the high achievers go?

Across every measure, Top Ten projects certainly exceed industry standards.

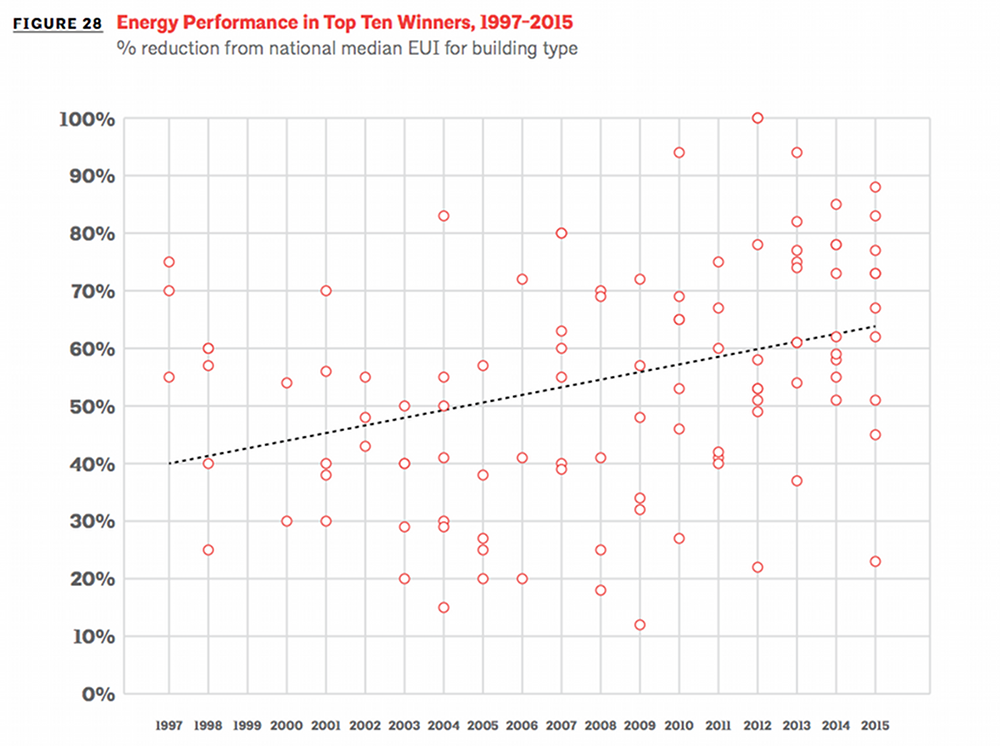

For example, the report found that Top Ten projects predicted 54% reduced energy on average from a baseline. Furthermore, the winners appear to be getting more successful, as average modeled energy reductions, which hovered around 35%–40% in the first decade, jumped to 65% in the latter decade.

That trajectory of progress should probably be taken with a grain of salt, however, for several reasons. First, only about half of the winners actually submitted a percentage for energy reduction; and second, the benchmarks themselves have changed. Projects pre-2010 used ASHRAE 90.1 as a baseline and based energy reductions on cost savings. The benchmark switched in 2010 to be consistent with Energy Star Portfolio Manager and the 2030 Challenge, both of which use the 2003 national average determined by the Commercial Buildings Energy Consumption Survey, or CBECS. On a recent Top Ten submission, the difference between the two baselines was ten percentage points.

And although the projects landed well above average, as a group, Top Ten winners barely top AIA 2030 thresholds. That average 54% energy reduction is just four points above the maximum energy points rewarded in LEED (see Progress on 2030 Goals, Ten Years Later). Judging by the 2030 energy targets, Top Ten projects did better than their reporting peers but could be described as on track, considering the program’s goals. In 2014, the average modeled reduction was 67% for Top Ten winners, when the 2030 target was 60%. However, that’s still well above the industry average, and it is also well above the 36.9% average for all projects reporting to 2030.

Looking at materials, Top Ten projects did go above and beyond LEED thresholds. Locally sourced materials accounted for 36% on average (LEED’s threshold is 20%), and 82% of construction waste was diverted from landfills, compared to LEED’s 50%–75%.

Potable water reductions come in at about 52% below a baseline standard and have trended upward by 10% since 1997.

The traits of the winners

Is there a recipe for success? Not exactly, but a project’s type and location might help your odds. Of the 189 Top Ten winners, 41 are located in California—nearly triple the number in any other state. No projects have yet won in Mississippi, Alabama, South Carolina, or the whole region of the Upper Great Plains (Idaho, Montana, Wyoming, Nebraska, and the Dakotas). Only five winners are located outside North America.

Early on, office buildings were the most popular building type, according to the report, representing 30%–40% of all winners, but diversity in type has expanded, with more winners in residential and public projects in particular. Additionally, 75% of all Top Ten winners are new buildings, though projects utilizing adaptive reuse have increased in recent years (see 2014 AIA Top Ten Green Winners Highlight Adaptive Reuse). “This trend could signal wider adoption of green building across various markets,” says the report.

It is worthy of note that Top Ten winners generally remain relatively small: 70% are under 100,000 ft2, and roughly half are under 50,000 ft2. That’s not to say that small firms have a leg up: two-thirds of Top Ten winners are from large firms. That’s not representative of the AIA membership, where 97% of members are sole practitioners or have fewer than 50 employees. “Larger firms may have more success with Top Ten Awards because they have more work and therefore more opportunity for success,” according to the report.

Room for progress

In terms of performance, the report also points out areas for improvement. In 2009, a COTE-sponsored study of 28 Top Ten winners found that, in about a third of the projects, actual energy use differed substantially from what had been predicted. Going forward, actual energy performance information will be requested in the submission forms for all Top Ten entries, starting with the applicants for the 2016 awards.

Top Ten projects also didn’t appear to be as far out on the leading edge as one might expect in two important areas: material health and post-occupancy evaluations (POEs). Roughly half mention using finishes and materials with low VOCs, but only 16% referenced any other material health strategy. Three projects cited the Living Building Challenge Red List, and none have listed Health Product Declarations (though that framework launched relatively recently, in 2012). In addition, only half of the winners conducted POEs, though the numbers have trended upward since 2003.

Top Ten projects also didn’t appear to be as far out on the leading edge as one might expect in two important areas: material health and post-occupancy evaluations (POEs). Roughly half mention using finishes and materials with low VOCs, but only 16% referenced any other material health strategy. Three projects cited the Living Building Challenge Red List, and none have listed Health Product Declarations (though that framework launched relatively recently, in 2012). In addition, only half of the winners conducted POEs, though the numbers have trended upward since 2003.

The news about cost isn’t entirely rosy either. For the 13 net-zero-energy Top Ten winners, cost per square foot was 22% higher than the average for all Top Ten projects. That comparison doesn’t take into account differences in project type or local markets, but it may suggest that the most energy-efficient projects come at a higher price point. Still, more than 70 projects have been built for less than $250 per square foot, notes the report, and most of those achieved more than a 50% energy reduction compared to a baseline.

Staying on mission

The report also attempts to evaluate the program’s success in its mission of bringing together “design excellence” and sustainable performance. Thirteen projects have achieved both a Top Ten award and an AIA Institute of Honor Award, most of them in the past six years. This could indicate that the two standards are progressively aligning. And in fact, based on the research team’s own scoring, projects have gotten better and better at achieving both since the Top Ten’s inception in 1997.

More on the Top Ten Awards

AIA Top Ten Projects Demonstrate High Ideals on a Real-World Budget

New “Top Ten Plus” Award Crowns AIA’s 2013 Green Projects

AIA Honor Awards to Be Judged on Sustainability

Add new comment

To post a comment, you need to register for a BuildingGreen Basic membership (free) or login to your existing profile.